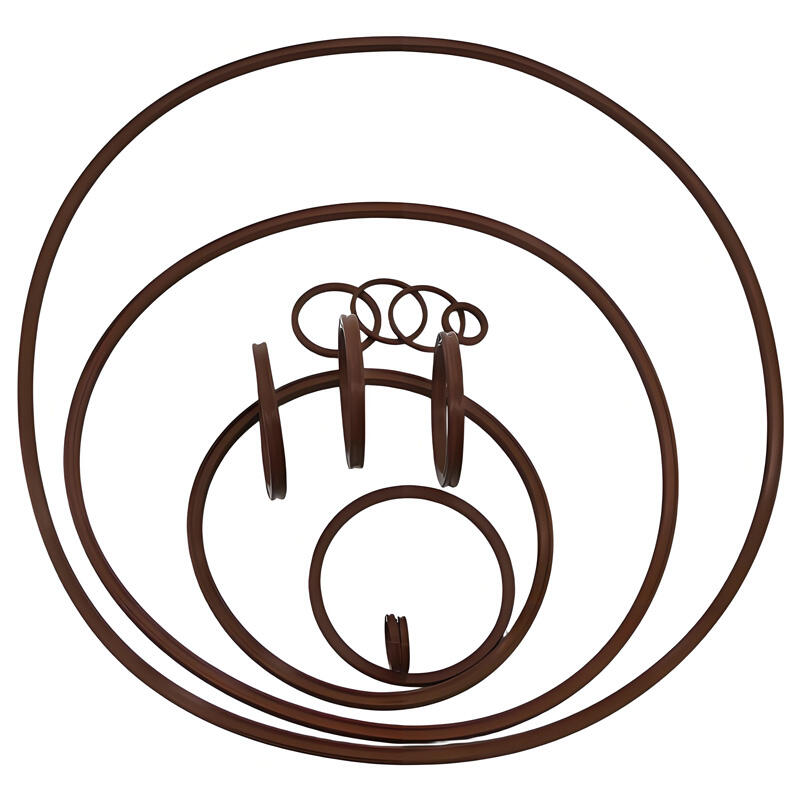

high temperature oil seal

High temperature oil seals represent a crucial advancement in industrial sealing technology, engineered specifically to maintain integrity and performance under extreme thermal conditions. These specialized sealing solutions are designed to withstand temperatures ranging from 150°C to over 300°C while preventing oil leakage and maintaining system efficiency. The construction typically involves advanced fluoroelastomer or perfluoroelastomer materials, reinforced with high-strength backing rings and specialized surface treatments that enhance durability. These seals incorporate innovative lip designs that maintain consistent contact pressure even as temperatures fluctuate, ensuring reliable sealing performance across diverse operating conditions. Their primary function extends beyond simple containment to include protection against contamination, reduction of friction, and maintenance of proper lubrication within critical mechanical systems. Industries such as aerospace, automotive manufacturing, and heavy industrial processing rely on these seals for their critical equipment where standard sealing solutions would quickly deteriorate. The design incorporates specific features like multiple sealing lips, integrated heat dissipation channels, and specialized coating technologies that contribute to extended service life and reduced maintenance requirements.