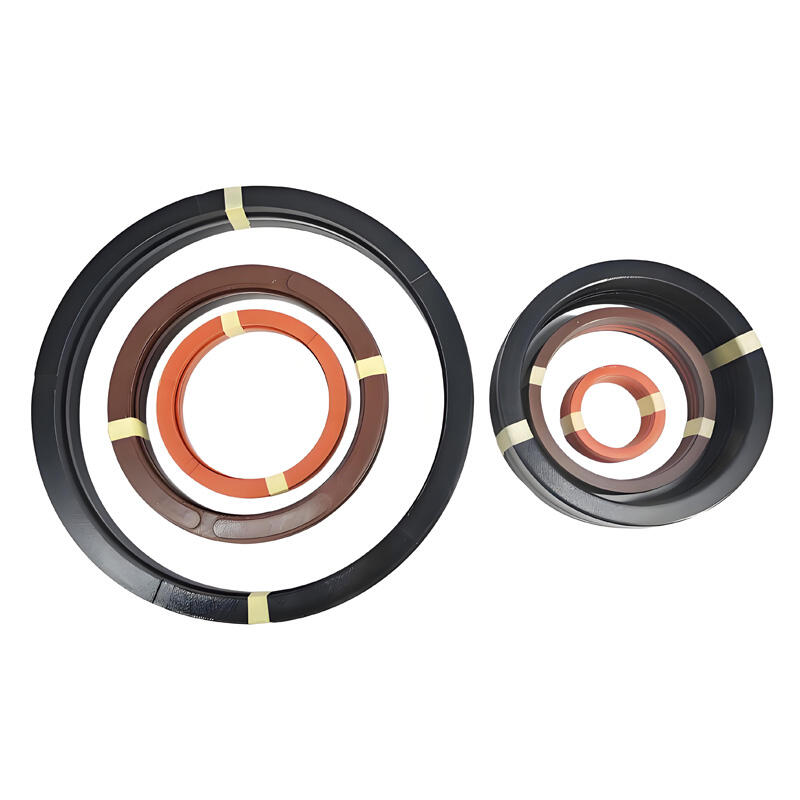

piston oil seal

A piston oil seal is a critical component in mechanical systems designed to prevent oil leakage and maintain system integrity. This specialized sealing device creates an effective barrier between the piston and cylinder wall, ensuring optimal performance in various applications. The seal consists of high-grade elastomeric materials engineered to withstand extreme temperatures, pressures, and chemical exposure. Modern piston oil seals incorporate advanced lip designs that provide bidirectional sealing capability, effectively containing lubricants while preventing external contaminants from entering the system. The seal's dynamic design allows for smooth reciprocating motion while maintaining consistent contact pressure against the cylinder wall. Manufacturing processes employ precision molding techniques to ensure dimensional accuracy and surface finish quality, crucial for reliable sealing performance. These seals are widely used in hydraulic cylinders, pneumatic systems, automotive engines, and industrial machinery where fluid containment is essential. The seal's profile is carefully engineered to optimize contact pressure distribution, minimizing friction while maximizing sealing effectiveness. Advanced materials selection ensures long-term durability and resistance to degradation, even in challenging operating environments. The integration of support rings and reinforcement elements enhances structural stability and prevents deformation under high-pressure conditions.